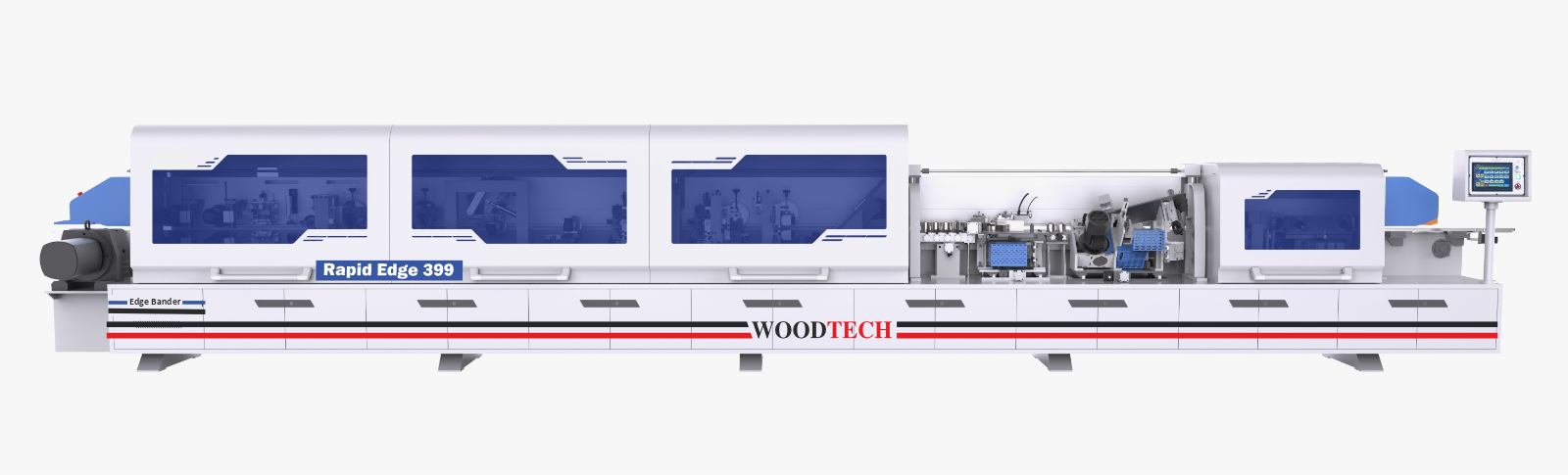

| MODEL | Rapid Edge - 399 |

| Min. Width of the Panel: Straight edge | ³90mm; Bevel edge: ³150mm |

| Min. Length of the Panel: Straight edge | ³120mm; Beveled edge: ³150mm |

| Min. Thickness of the Panel: Straight edge | 9-60mm; beveled edge: 9~25mm |

| Edge Dimensions in Strips: Straight edge | 0.4-3mm; bevel edge: 0.45~1.5mm |

| Feed Speed: Straight edge | 15~24m/min; bevel edge: 15-18m/min |

| Glue Tank Capacity | bevel (1.1kg for straight,2.1kg for bevel),3kg for straight |

| Glue Motor | 0.75kWX3 |

| Heating power | bevel (straight 1.95kW,bevel 2.1kW),straight2.35kW |

| Anti-Adhesive Unit | Yes |

| Power of pre milling unit | Straight side: 3.7kWX2,bevel side5.5kWX2 |

| Power of End Trimming Unit | 0.37kWX2 |

| Power of edge tape grooving | 0.75kW |

| power of rough trimming | 0.75kWX2 |

| power of fine trimming | 0.75kWX4 |

| Edge Scraping Unit | 2 teams |

| Flat Scraping Unit | Group 1 |

| Spraying | Yes |

| Buffing unit (2 Motors) with cloth disc | 0.37kWX4 |

| Conveyor Motor | 5.5kW |

| Beam Lifting Motor | 0.37kWX2 |

| Electric lifting position | Two places in the middle |

| Dust Capacity (m3/h) | 14750 |

| Suction Air Volume | 30m/s |

| Air consumption | 1020 L/min |

| Angle adjustment range | Fixed 45 degrees |

| Installed power | 42.74kW |

| Working pressure | 0.6mpa |

| Packing size(LXWXH) | 1345X1200X1960 |

| Overall size(LXWXH) | 10292X990X1960 |

| Voltage | 415V/50HZ/3P |

Features

1. 14-inch touch screen - With intelligent temperature control. It can be set to keep warm when the device is not working, which reduces power consumption and carbonization of the glue.

2. Pressure beam with V-belt - Steel-made top pressure beam with V-belt ensures stable feeding.

3. Milling unit - With intelligent temperature control. It can be set to keep warm when the device is not working, which reduces power consumption and carbonization of the glue.

4. Edge tape grooving - Slotting and forming the edge to achieve a clear finish.

5. Straight/ bevel end pressing - Double glue-pressing unit, independently configured for beveled and straight edge gluing and pressing to facilitate adjustment and ensure a tight fit of the edge banding strip.

6. End cutting unit - End cutting unit removes excess edge banding strip to ensure a smooth and flat cut-off surface.

7. Trimming unit - Rough trim applies to trim off the excessive glue on top and bottom of workpiece; fine trim applies for R profiling.

8. Straight edge corner round - Corner rounding unit: achieves multiple types of edge trimming processes.

9. Straight/ bevel scrapping unit - Double scraping unit for beveled and straight edges remove the ripple marks to make the upper and lower parts of the board smoother and cleaner.

10. Flat Scraping Unit - The flat scraping mechanism removes the glue line on the edge of the board to make a better finishing.

11. Buffing units - Clean off dust on the workpiece to ensure for a clean and smooth finishing.

12. Clean and Spray unit.

13. Pressure beam with auto adjustment.

Optional Devices: PUR Melter and PUR Quick Change Glue Pot.